DESCRIPTION OF LIPP SYSTEM

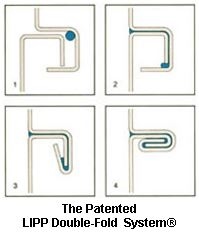

LIPP System is a worldwide patented and applied technology for the construction of tanks according to the LIPP double-fold system which enables on-sites automated and rational production of widely varying cylindrical steel tanks within a very short space of time. The system is suitable for sizes ranging from 3 meters and over 40 meters in diameter and up to 30 meters in height.  The patented fold joint is what makes the The patented fold joint is what makes the LIPP tank advantageous. It runs in a spiral around the whole tank and in this way bears all horizontal pressure which is applied to any part of the structure. The fold is completely gas-tight and creates a surface which is free from grooves and edges on the inside of the tanks. Depending on customer’s requirements, special machines are transported to the construction site together with the materials to be used in the production, and will be erected in modular system on-site.

The material which is necessary for the production of the tanks is cut to size in factory and rolled into one or more coils. The type and strength of the materials depend on the respective static requirements and what the container is to be used for. A wide spectrum of the material choices ranges from non-ferrous metals to galvanised steel and high-alloyed steels are available. For optimum cost consideration, the combination of two materials such as galvanised steel on external and stainless steel on internal, is possible, depending on the requirement of the specific application.

|

LIPP Tank for Liquids, Gas, Sewage, Sludge and Bulk StorageMade Of Stainless Steel or Galvanised Steel to a Patented Process from 15 m3 to 7,000 m3 Capacity

Materials: Material to be used for the tank is selected based on the chemical and physical properties of the medium to be stored. Another factor for material selection is the budget aspect. For storing corrosive fluids such as sewage, sludge or slurry, LIPP uses a combine galvanized steel on the outer side of the tank as the base material and stainless steel on the inner side of the tank, appropriate to the medium.

Fittings:

Fittings and accessories for LIPP System includes tank roofs, bases, pumps, mixing technology, tank insulation, broach bridging, overflow pipes, steps, ladders, platforms, tank bushings, etc. In order to achieve a perfect and tight fit, a permanently elastic sealing compound is applied into the fold prior to the actual connection or folding process.

Fields of Application:

1. Storage of liquids and bulk items for municipal, industrial and agricultural purposes;

2. Potable water storage tanks, rain water storage tanks,

3. Waste water treatment or storage tanks,

4. Fire-fighting water storage tanks,

5. Buffer tanks, sewage treatment biological-tanks, sludge holding tanks, sedimentation tanks and anaerobic digesters tanks (for biogas plants),

6. Oil and gas storage tanks,

7. Silos for storage of dry agricultural products or raw materials.

|

|